Weiss Envirotronics is a worldwide leader in the design, manufacturer and service of environmental test chambers. A complete line of standard and custom chambers, from bench top models to full walk-in and drive-in solutions to meet any testing requirement. Not sure what you need? Let one of our applications engineers help. Weiss Envirotronics, Inc is ISO 9001 registered and A2LA accredited.

Complete finishing systems are designed around your specific process needs and are optimized to fit within your space requirements. We specialize in producing paint systems for wet and powder coatings, while also providing comprehensive design, fabrication, installation, start-up, and training services. Our complete finishing systems consist of an overhead conveyor, pretreatment washer, dry-off...

Surface Combustion offers a diverse product offering for batch, continuous furnace designs for atmosphere, non-atmosphere, or vacuum processing of ferrous and/or nonferrous components/materials. The convection design is optimal for temperatures between 350°F – 1400°F and are engineered to perform and built to last.

Since 1961, Thermal Engineering’s process & finishing systems contribute to the product quality of many automobile, furniture, paper, plastic & building products. Thermal’s industrial ovens offer savings in regards to time, energy & space and its solutions are designed for maximum flexibility for customers' use and with all applicable safety & code requirements that encompass a quality system.

Kleenair Products designs, engineers and manufactures high quality industrial ovens for industrial process systems. Our aging ovens, coloring ovens, drying ovens and food baking ovens serve many industries. We test fire each oven before shipping, guaranteeing your satisfaction. You will also find other process systems at Kleenair, including furnaces, drying systems, and energy recovery equipment.

C.A. Litzler Co. is ready to help you with your heat processing needs. With 60 years of designing and manufacturing experience, you can rest assured that the industrial oven you need can be built by us. We are determined to find the product that will meet your every need and requirement. Visit our website or give us a call today to learn more about how we can meet your needs.

Industrial ovens are thermal processing machines essential for heat treatment applications. This process accelerates molecular activity within an object. In solids, heat causes lattice vibrations, while in gases, molecules collide. This molecular activity alters and strengthens the object’s properties. No two custom ovens are identical, but industrial ovens typically include these components: a motor for power, a duct distribution network for ventilation, exhaust and recirculation fans, purge timers, flame controllers, and burners.

Note: Industrial ovens differ from furnaces. Furnaces reach higher temperatures (over 2000℉) and are much larger. However, many industrial manufacturers also produce furnaces.

Applications of Industrial Ovens

Industrial ovens serve a broad spectrum of industries, including manufacturing, electronics, food and beverage, healthcare, pharmaceuticals, chemicals, research and development, plastics, aerospace, automotive, and metalforming. These ovens enhance the strength of metal products, ensure sanitary healthcare environments, and produce versatile extruded polymer products. They are used for treating steel coils, automotive parts, tubing, electronics, building materials, fuel cells, carpeting, and textiles. Laboratories also utilize laboratory ovens to study and improve industrial heat transfer processes, reducing inefficiencies and enabling new heat treatment applications.

Specifically, industrial ovens are employed for sintering, curing, and powder coating processes. Sintering involves creating larger particles from fine ones by applying heat below the melting point. Curing solidifies materials through consistent heating and drying. In powder coating, a product is heated in an oven, causing the powder to melt and flow. It is then briefly exposed to ultraviolet light to cure and harden the finish.

History of Industrial Ovens

Ovens have been in use since at least 2900 BC in Central Europe, originally employed in boiling and roasting pits for cooking mammoths inside yurts. Shortly thereafter, methods evolved to include hot coals covered by ashes. Within 300 years, hearths became common for cooking food and making bricks. These hearth-style brick ovens eventually led to the Greek invention of kilns for pottery and bread baking. Subsequent innovations saw the replacement of ceramic and earth ovens with fireplaces and cauldrons. Over time, ovens were powered by coal, wood, iron gas, and eventually, electricity.

The Industrial Revolution marked a significant advancement for industrial ovens. In the 1700s, Philo Penfield Stewart invented the Stewart Oberlin iron oven, which was smaller than previous designs and included a ventilation chimney. The early 1800s saw the introduction of coal ovens, and in 1826, James Sharp patented the first gas oven. Gustaf Dalen improved the gas oven with the AGA cooker in 1922, and in 1946, Percy Spencer introduced the microwave. Today, microwaves and other high-tech ovens are available in various sizes for diverse applications.

How Industrial Ovens Work

Industrial ovens utilize heat and mass transfer through radiant infrared heat, conduction, convection, or a combination of these methods. Infrared radiation is the most efficient method of heat transfer. Natural convection, the simplest method, relies on gravity to circulate fluid, causing heated molecules to rise and cool molecules to fall. Convection transfers heat between objects via gases (e.g., natural gas, propane) and liquids. Conduction, a less common method, involves transferring heat to the air inside the oven, which then heats a solid object. Other heat transfer methods exist but are less efficient and seldom used.

Types of Industrial Ovens

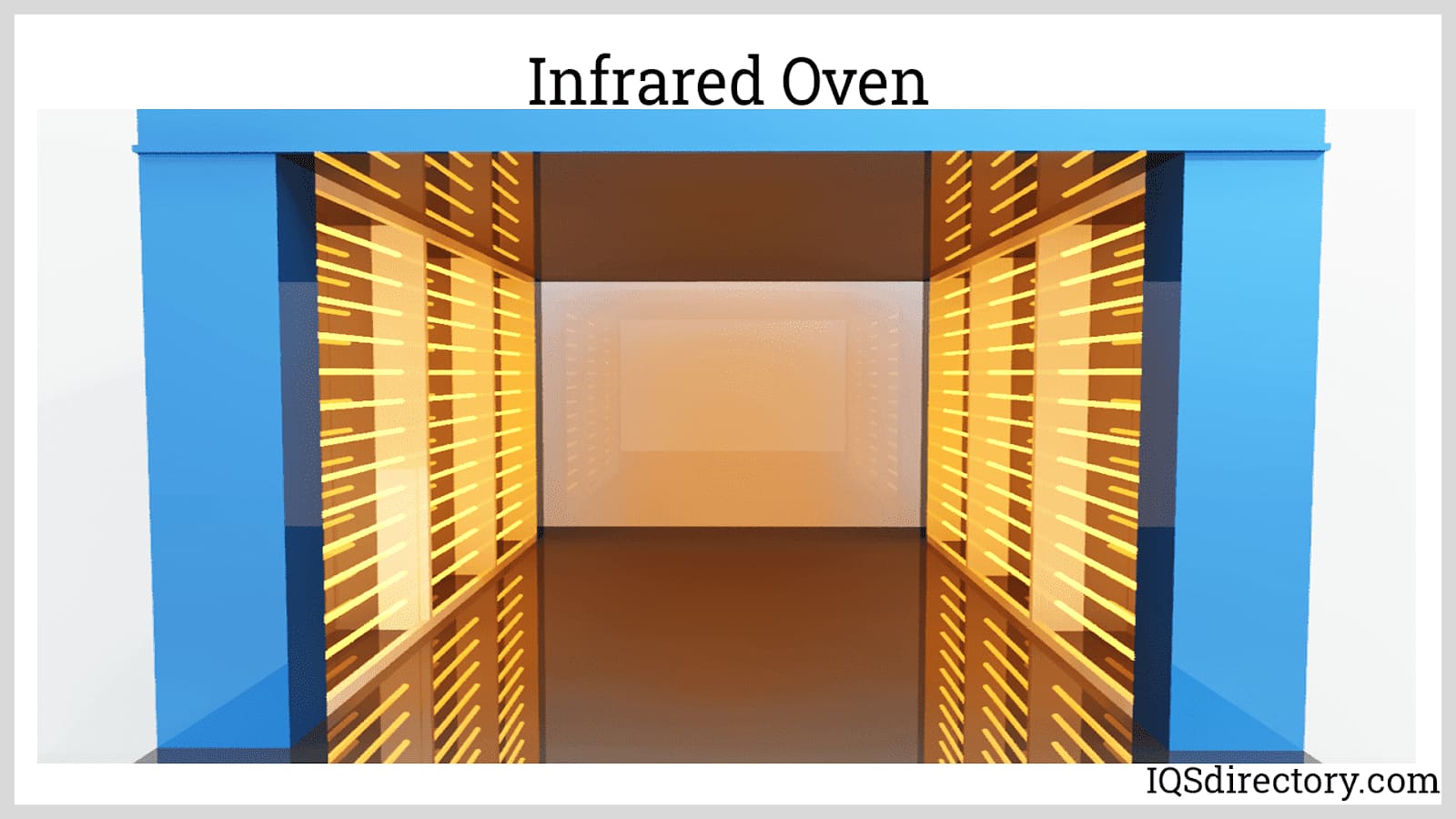

Infrared Oven

Infrared ovens utilize electromagnetic radiation for heat transfer, directly transferring waves from a tungsten coil to the product without heating the air inside the enclosure.

Convection Oven

Convection ovens, using either an electric coil or a gas-fired heating element, provide consistent interior heating. This method is ideal for small batches; larger batches require a fan for even heat distribution. These ovens are common in larger baking operations.

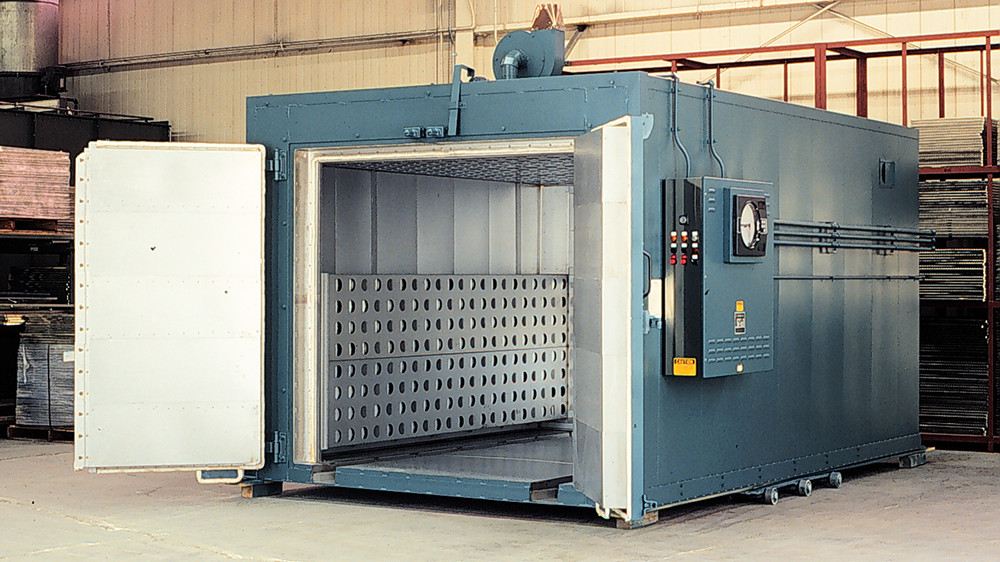

Batch Oven

Industrial batch ovens, ranging from small and portable to large and permanent, process materials in individual batches. They are favored by commercial manufacturers for processing large groups of individual products and by small industrial heat treat providers for their even heat application. Also known as cabinet or walk-in ovens, batch ovens can perform various processes such as curing, drying, annealing, or aging.

Vacuum Oven

Vacuum ovens are a type of batch oven designed to prevent surface oxidation of heat-treated metals by allowing the atmosphere within the enclosure to escape.

Continuous Oven Continuous ovens can handle multiple applications simultaneously, thanks to their separate warming and cooling stations. These ovens are ideal for mass processes requiring consistent thermal treatment due to their efficiency. Both batch and continuous ovens can function as sintering, heavy-duty powder coating, drying, or curing ovens.

Conveyor Oven

Conveyor ovens use an automated conveyor belt to move products through a heating chamber continuously. They are cost-effective only for large-scale operations with a constant flow of products.

Drying Oven

Drying ovens remove moisture from raw materials through a three-step process: heat-up, soak, and cool-down. They are ideal for sterilization, temperature-sensitive experiments, and temperature testing.

Tunnel Oven

Tunnel ovens heat materials moving through on a conveyor belt using various fuels. They are perfect for cooking food, especially meat and baked goods.

Burn-off Oven

Burn-off ovens, or heat-cleaning ovens, burn off contaminants like varnish, paint, grease, epoxy, oil, and bonded rubber. They are used for cleaning and decoating automotive parts and machinery.

How to use Industrial Ovens

Each oven model varies, so specific instructions may differ, but here are general guidelines. Select an installation location that is protected from high temperatures, mechanical damage, and vibrations. Avoid placing the oven directly against a wall. For stainless steel cabinets, use a shim to level the oven, accounting for expansion during heating. Ensure adequate ventilation at the installation site. Adhere to all relevant standards, specifications, and codes during installation and use. If you are unsure about installing your industrial oven, contact your supplier for assistance or professional support.

Benefits of Industrial Ovens

Industrial ovens are prized for their air flow efficiency, speed, durability, consistency, easy temperature management, and cost-effectiveness. The air flow efficiency of industrial ovens ensures uniform temperature distribution, critical for smooth heating performance. They also generate heat rapidly without excessive energy consumption, allowing for the quick completion of tasks. Constructed primarily from stainless steel, these ovens are both durable and highly reliable. Temperature management is straightforward, minimizing the risk of uneven heating. Despite varying prices, industrial ovens are relatively affordable and offer excellent long-term investment value due to their reliability.

Designs of Industrial Ovens

When designing an industrial oven, manufacturers assess various factors, starting with its intended application—whether for food-grade use or manufacturing equipment. This determines the oven’s functionality, power source (gas or electric), and temperature requirements. Manufacturers can customize the oven to meet specific needs.

Things to Consider

To find the right manufacturer, start by reviewing a list of reputable sources. This page provides a curated selection of experienced and reputable industrial oven companies, complete with profiles. Allocate some time to browse these profiles and company websites to identify those that meet your needs. Select three or four companies for further inquiry. When contacting them, ensure they offer essential services such as standard certifications, factory testing and troubleshooting, delivery, installation, and after-installation maintenance support. Once you identify a suitable manufacturer, initiate further communication to proceed with your project.

More Oven Manufacturers

What is an industrial oven and how does it work?

An industrial oven is a thermal processing machine used for heat treatment applications, accelerating molecular activity within materials to alter and strengthen their properties. Industrial ovens use methods like conduction, convection, and radiant infrared heat to transfer energy, enabling processes such as curing, drying, and sintering in various industries.

What are the main components of an industrial oven?

Industrial ovens typically contain a motor for power, a duct distribution network for ventilation, exhaust and recirculation fans, purge timers, flame controllers, and burners. Each custom oven may be designed differently based on specific application requirements.

How do industrial ovens differ from furnaces?

Industrial ovens are designed for heat treatment processes at moderate to high temperatures, but furnaces are much larger and can reach temperatures above 2000℉. Furnaces are used for processes that require extremely high temperatures, while industrial ovens serve a broader range of applications at lower heat levels.

What industries use industrial ovens?

Industrial ovens are used in manufacturing, electronics, food and beverage, healthcare, pharmaceuticals, chemicals, research and development, plastics, aerospace, automotive, metalforming, and laboratories for processes such as curing, sterilizing, drying, and heat treating various materials and products.

What are the main types of industrial ovens?

The main types include infrared ovens, convection ovens, batch ovens, vacuum ovens, continuous ovens, conveyor ovens, drying ovens, tunnel ovens, and burn-off ovens. Each type is designed for specific applications such as heat treating, drying, cleaning, or coating materials.

What are some benefits of using industrial ovens?

Industrial ovens offer efficient air flow, rapid heating, durability, consistent results, easy temperature management, and cost-effectiveness. They are constructed from durable materials such as stainless steel and provide reliable, uniform heating that is energy-efficient and suitable for a wide range of applications.

What should be considered when using or installing an industrial oven?

Install industrial ovens in areas protected from high temperatures, mechanical damage, and vibrations. Ensure proper ventilation and avoid placing the oven directly against walls. Follow all safety codes and standards. Contact your supplier if you need help with installation or have specific operational questions.

Electric Heaters

Electric Heaters Industrial Dryers

Industrial Dryers Industrial Mixers

Industrial Mixers Industrial Ovens

Industrial Ovens Pressure Vessels

Pressure Vessels Pulverizers

Pulverizers Vibratory Feeders

Vibratory Feeders Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services